沼氣發(fā)電工程余熱利用相關(guān)知識(shí)介紹

沼氣是一種清潔的能源,不僅有助于減輕溫室效應(yīng)、促進(jìn)生態(tài)環(huán)境良性循環(huán),而且可替代石油、煤炭等化石燃料,成為解決能源與環(huán)境問題的重要途徑,利用沼氣發(fā)電不僅可以緩解電力供應(yīng)緊張的現(xiàn)狀,而且在發(fā)電過程中產(chǎn)生的余熱也有很高的利用價(jià)值。

Biogas is a kind of clean energy, which not only helps to reduce the greenhouse effect and promote the virtuous cycle of ecological environment, but also can replace fossil fuels such as oil and coal. It has become an important way to solve the energy and environmental problems. The use of biogas power generation can not only alleviate the current situation of power supply shortage, but also has high utilization value in the process of power generation.

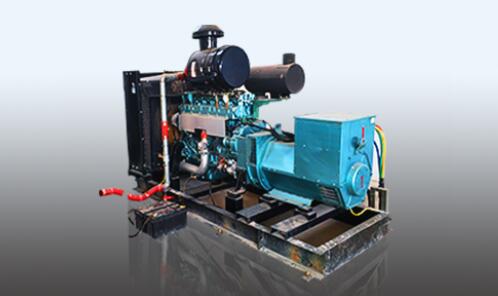

沼氣發(fā)電機(jī)在發(fā)電的同時(shí),煙氣溫度一般在550℃左右,通過余熱回收技術(shù),將燃?xì)鈨?nèi)燃機(jī)中的潤(rùn)滑油、中冷器、缸套水和煙氣排放中的熱量充分回收利用,用于冬季采暖以及生活熱水。夏季可與溴化鋰吸收式制冷劑連接,作為空調(diào)制冷。一般從內(nèi)燃機(jī)余熱回收系統(tǒng)中吸收的熱量以90℃的熱水供給熱交換部分使用。內(nèi)燃機(jī)正?;厮疁囟葹?0℃。

Biogas generator generates electricity at the same time, the flue gas temperature is generally about 550 ℃. Through the waste heat recovery technology, the lubricating oil, intercooler, cylinder liner water and heat from flue gas emission in gas-fired internal combustion engine are fully recovered and utilized for heating and domestic hot water in winter. In summer, it can be connected with lithium bromide absorption refrigerant as air conditioning refrigeration. Generally, the heat absorbed from the internal combustion engine waste heat recovery system is supplied to the heat exchange part with 90 ℃ hot water. The normal return water temperature of internal combustion engine is 70 ℃.

沼氣發(fā)電機(jī)組余熱的利用方式,大體分為兩種,一種是排煙的余熱利用,另一種是發(fā)電機(jī)組冷卻熱量的利用,常見的余熱利用方式一般有熱水型、煙氣型、蒸汽型、發(fā)電型四種。其中熱水型是利用發(fā)電機(jī)余熱產(chǎn)生90度或更高溫度的熱水,這種方式一般用于需要供暖的北方地區(qū),煙氣型是利用煙氣的余熱配合吸收式制冷機(jī)組,提供冷源負(fù)荷;蒸汽型是利用煙氣余熱產(chǎn)生飽和蒸汽或者過熱蒸汽,=一種發(fā)電型則是利用發(fā)電機(jī)余熱,配合螺桿膨脹動(dòng)力機(jī)發(fā)電。

There are two ways to use the waste heat of biogas generator set, one is the use of exhaust heat, the other is the use of cooling heat of generator set. There are four common ways to use the waste heat: hot water type, flue gas type, steam type and power generation type. The hot water type uses the waste heat of the generator to generate hot water of 90 degrees or higher, which is generally used in northern areas where heating is needed. The flue gas type uses the waste heat of the flue gas to cooperate with the absorption refrigeration unit to provide the cold source load; The steam type uses the waste heat of flue gas to generate saturated steam or superheated steam, while the power generation type uses the waste heat of generator to generate power with screw expansion power machine.

目前,大多數(shù)發(fā)電設(shè)備將余熱利用設(shè)備與發(fā)電機(jī)組集成一體化,即換熱裝置在機(jī)組內(nèi)部,不用單獨(dú)配置。設(shè)備只需要三個(gè)接口:進(jìn)、回水接口和沼氣接口,設(shè)備可與熱水鍋爐并聯(lián)連接,既簡(jiǎn)化了系統(tǒng),減少了設(shè)備及占地面積,利于運(yùn)行維護(hù),同時(shí)也減少了系統(tǒng)工程總投資,據(jù)統(tǒng)計(jì),沼氣發(fā)電余熱綜合種用率可達(dá)80%,在發(fā)電并網(wǎng)的同時(shí),減少了能源消耗,方便了電站的給管理,也提高了沼氣發(fā)電工程的自我供應(yīng)能力。

At present, most of the power generation equipment integrates the waste heat utilization equipment with the generator set, that is, the heat exchange device is inside the unit, and there is no need to configure it separately. The equipment only needs three interfaces: inlet and return water interface and biogas interface. The equipment can be connected in parallel with the hot water boiler, which not only simplifies the system, reduces the equipment and floor area, is conducive to operation and maintenance, but also reduces the total investment of system engineering. According to statistics, the comprehensive utilization rate of waste heat from biogas power generation can reach 80%, and reduces energy consumption while connecting the power generation to the grid, It not only facilitates the management of power station, but also improves the self supply capacity of biogas power generation project.

在線咨詢

在線咨詢 官方二維碼

官方二維碼

當(dāng)前位置:

當(dāng)前位置: 2021.05.31

2021.05.31