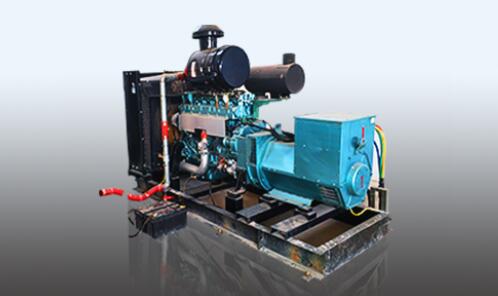

沼氣預(yù)處理對(duì)沼氣發(fā)電機(jī)組的影響

在利用沼氣發(fā)電過程中,由于沼氣發(fā)電機(jī)組本身設(shè)計(jì)和材料的特點(diǎn),導(dǎo)致發(fā)電機(jī)組對(duì)沼氣中的部分成分(如H2S、水分、固體雜質(zhì)等)特別敏感,如果處理不好將導(dǎo)致發(fā)電機(jī)組無法正常運(yùn)行。

In the process of using biogas for power generation, due to the design and material characteristics of the biogas generator unit itself, it is particularly sensitive to some components in the biogas (such as H2S, moisture, solid impurities, etc.). If not handled properly, it will cause the generator unit to be unable to operate normally.

1 硫化氫對(duì)發(fā)電機(jī)組的影響

The impact of hydrogen sulfide on generator sets

硫化氫(H2S)是一種無色有毒的可燃性氣體,具有強(qiáng)烈的臭雞蛋氣味,當(dāng)空氣中硫化氫的體積含量超過0.1%時(shí),就能引起頭疼暈眩等中毒癥狀。硫化氫(H2S)對(duì)鐵等金屬有強(qiáng)腐蝕性,也易吸附金屬表面與多種金屬離子作用,生成不溶于水的硫化物沉淀。沼氣在燃燒時(shí),其中的H2S還能轉(zhuǎn)化為腐蝕性很強(qiáng)的亞硫酸氣霧會(huì)污染環(huán)境和腐蝕機(jī)器設(shè)備,同時(shí)H2S在潮濕的環(huán)境下對(duì)金屬管道、燃燒設(shè)備、檢測(cè)設(shè)備和儀表等都具有強(qiáng)烈的腐蝕性,所以沼氣在利用前必須脫出其中所含的H2S。利用沼氣發(fā)電時(shí)沼氣中的硫化氫會(huì)對(duì)沼氣發(fā)電機(jī)組的進(jìn)氣管道、增壓器、中冷器、火花塞、氣缸套、排氣管和消音器等造成嚴(yán)重腐蝕影響機(jī)組壽命。所以沼氣在進(jìn)入發(fā)電機(jī)組之前必須進(jìn)行沼氣預(yù)處理,將H2S降到機(jī)組允許的范圍內(nèi)才能保證機(jī)組的可靠運(yùn)行。

Hydrogen sulfide (H2S) is a colorless, toxic, flammable gas with a strong odor of rotten eggs. When the volume content of hydrogen sulfide in the air exceeds 0.1%, it can cause poisoning symptoms such as headaches and dizziness. Hydrogen sulfide (H2S) has strong corrosiveness to metals such as iron and is also prone to adsorbing metal surfaces and interacting with various metal ions to form insoluble sulfide precipitates. During the combustion of biogas, H2S can also be converted into highly corrosive Sulfurous acid mist, which will pollute the environment and corrode machinery and equipment. At the same time, H2S is highly corrosive to metal pipes, combustion equipment, detection equipment and instruments in a humid environment, so the H2S contained in biogas must be removed before use. The hydrogen sulfide in the biogas will cause serious corrosion to the intake pipe, supercharger, Intercooler, spark plug, cylinder liner, exhaust pipe and silencer of the biogas generator set when generating power with biogas, and affect the service life of the unit. So before biogas enters the generator unit, it must undergo biogas pretreatment to reduce H2S to the allowable range of the unit in order to ensure the reliable operation of the unit.

2 水分對(duì)發(fā)電機(jī)組的影響

2. The impact of moisture on generator sets

在利用沼氣發(fā)電過程中,沼氣水分含量過大的話,會(huì)導(dǎo)致發(fā)電機(jī)組的進(jìn)氣壓力損耗過大,嚴(yán)重的情況下,會(huì)引起發(fā)動(dòng)機(jī)功率波動(dòng)、敲缸、停機(jī)等嚴(yán)重地影響其使用壽命。其具體表現(xiàn)為:

In the process of using biogas for power generation, if the moisture content of biogas is too high, it will lead to excessive loss of intake pressure of the generator set. In severe cases, it can cause engine power fluctuations, cylinder knocking, shutdown, and seriously affect its service life. Its specific manifestation is:

(a)發(fā)動(dòng)機(jī)點(diǎn)火困難;

(a) Difficulty in engine ignition;

(b)降低燃燒室溫度,降低內(nèi)燃機(jī)的效率;

(b) Reduce the temperature of the combustion chamber and reduce the efficiency of the internal combustion engine;

(c)由于水蒸氣等無功氣體的存在,增壓耗功增大;

(c) Due to the presence of reactive gases such as water vapor, the power consumption of turbocharging increases;

(d)水蒸氣與其他酸性物質(zhì)的化合產(chǎn)生中間產(chǎn)物,對(duì)機(jī)器本身產(chǎn)生腐蝕,縮短機(jī)器的使用壽命,降低機(jī)器的可靠性。

(d) The combination of water vapor and other acidic substances produces intermediate products that corrode the machine itself, shorten its service life, and reduce its reliability.

3 固體雜質(zhì)對(duì)發(fā)電機(jī)組的影響

3. The impact of solid impurities on the generator set

粉塵是大氣環(huán)境中涉及面廣、危害嚴(yán)重的一種污染物。粉塵是發(fā)動(dòng)機(jī)明確限制的雜質(zhì),它主要影響在于:

Dust is a widely involved and severely harmful pollutant in the atmospheric environment. Dust is a clearly restricted impurity in engines, and its main impact is:

(a)堵塞管路,流通不暢,加大壓損,增加運(yùn)行費(fèi)用;

(a) Blocking the pipeline, poor circulation, increased pressure loss, and increased operating costs;

(b)增大機(jī)械磨損,降低設(shè)備使用壽命。

(b) Increase mechanical wear and reduce equipment service life.

針對(duì)發(fā)動(dòng)機(jī)對(duì)沼氣的要求,在沼氣發(fā)動(dòng)機(jī)前安裝處理系統(tǒng)以解決了氣源側(cè)與用氣側(cè)的矛盾是目前解決沼氣發(fā)電機(jī)組利用問題的有效方法,主要表現(xiàn)在以下兩個(gè)方面:

In response to the requirements of the engine for biogas, installing a processing system in front of the biogas engine to solve the contradiction between the gas source side and the gas consumption side is currently an effective method to solve the utilization problem of biogas generator sets, mainly manifested in the following two aspects:

1 降低氣體的相對(duì)濕度

1. Reduce the relative humidity of the gas

水分的脫除,考慮到具體的情況,簡(jiǎn)單分為凝結(jié)水的脫除以及未凝結(jié)水脫除兩大部分,前者可以采用汽水分離器來實(shí)現(xiàn),后者的實(shí)現(xiàn)較為復(fù)雜,目前主要有下面幾種方式:

The removal of moisture, considering specific circumstances, can be simply divided into two parts: the removal of condensed water and the removal of uncondensed water. The former can be achieved by using a steam water separator, while the latter is more complex to achieve. Currently, there are mainly the following methods:

(a)低溫除濕:通過制冷設(shè)備降低氣體的溫度,使得其中的水蒸氣凝結(jié),然后排除系統(tǒng);

(a) Low temperature dehumidification: By using refrigeration equipment to reduce the temperature of the gas, the water vapor inside is condensed and then discharged from the system;

(b)吸附:采用對(duì)水有較強(qiáng)吸附作用的吸附劑,將氣體中的水分析出;

(b) Adsorption: Use an adsorbent with strong adsorption effect on water to analyze the water in the gas;

(c)膜過濾:采用特殊結(jié)構(gòu)的膜材料,在特定的條件下將水從氣體中分出。

(c) Membrane filtration: A membrane material with a special structure is used to separate water from the gas under specific conditions.

2 降低氣體雜質(zhì)成分含量

2. Reduce the content of gas impurities

氣體中的雜質(zhì)是比較復(fù)雜的成分,由于是針對(duì)發(fā)動(dòng)機(jī)的利用,所以對(duì)雜質(zhì)的判斷主要以發(fā)動(dòng)機(jī)的要求為準(zhǔn),主要有下面幾種:

Impurities in gases are relatively complex components, and as they are specific to the utilization of the engine, the determination of impurities is mainly based on the requirements of the engine, including the following:

(a)硫的去除:

(a) Sulfur removal:

以硫化氫為主的硫化物的去除主要有物理、化學(xué)以及生物三種方式。其中物理方法主要指物理吸附方式脫硫,這種方式操作簡(jiǎn)便,但往往需要占地較大的設(shè)備,而且吸附劑需要再生?;瘜W(xué)方式指以化學(xué)反應(yīng)的方式將硫固化下來,目前有干法及濕法,其差別主要是反應(yīng)物的物理形態(tài)是固體還是液體的差別。生物法脫硫是目前比較新興的一種方式,其主要原理是在反應(yīng)罐中培養(yǎng)出合適的菌種,這些菌種以硫化物為養(yǎng)料,將其中的硫固定下來。 對(duì)于硫含量不高的氣體,采用物理吸附或者干法脫硫一般比較經(jīng)濟(jì)實(shí)用,而且操作簡(jiǎn)便。

The removal of sulfides mainly composed of hydrogen sulfide mainly involves three methods: physical, chemical, and biological. The physical method mainly refers to the physical adsorption method for desulfurization, which is easy to operate but often requires a large area of equipment, and the adsorbent needs to be regenerated. Chemical method refers to the solidification of sulfur through chemical reactions. Currently, there are dry and wet methods, and the main difference is whether the physical form of the reactant is solid or liquid. Biological desulfurization is currently a relatively emerging method, whose main principle is to cultivate suitable bacterial strains in reaction tanks, which use sulfides as nutrients to fix the sulfur in them. For gases with low sulfur content, using physical adsorption or dry desulfurization is generally more economical and practical, and the operation is simple.

此外,根據(jù)我國的環(huán)保標(biāo)準(zhǔn)規(guī)定:沼氣作為能源利用時(shí),沼氣中的H2S含量不得超過200mg/Nm3。因此沼氣經(jīng)過脫硫處理后需要采用沼氣分析儀對(duì)沼氣中H2S含量進(jìn)行實(shí)時(shí)在線監(jiān)測(cè),為業(yè)主提供實(shí)時(shí)準(zhǔn)確的數(shù)據(jù)參考,幫助其對(duì)沼氣預(yù)處理工藝進(jìn)行優(yōu)化調(diào)整,提高沼氣發(fā)電機(jī)組進(jìn)氣品質(zhì),以保證H2S含量達(dá)到沼氣發(fā)電的要求。

In addition, according to China's environmental standards, when biogas is used as energy, the H2S content in biogas should not exceed 200mg/Nm3. Therefore, after the desulfurization treatment of biogas, a biogas analyzer needs to be used for real-time online monitoring of the H2S content in the biogas, providing real-time and accurate data reference for the owner, helping them optimize and adjust the biogas pretreatment process, improve the intake quality of the biogas generator unit, and ensure that the H2S content meets the requirements of biogas power generation.

本文由沼氣發(fā)電機(jī)組友情奉獻(xiàn).更多有關(guān)的知識(shí)請(qǐng)點(diǎn)擊:http://www.51credits.cn真誠的態(tài)度.為您提供為全面的服務(wù).更多有關(guān)的知識(shí)我們將會(huì)陸續(xù)向大家奉獻(xiàn).敬請(qǐng)期待.

This article is dedicated by the biogas generator unit. For more relevant knowledge, please click on: http://www.51credits.cn Sincere attitude. We will provide you with comprehensive services. We will gradually contribute more relevant knowledge to everyone. Stay tuned

在線咨詢

在線咨詢 官方二維碼

官方二維碼

當(dāng)前位置:

當(dāng)前位置: 2023.07.06

2023.07.06